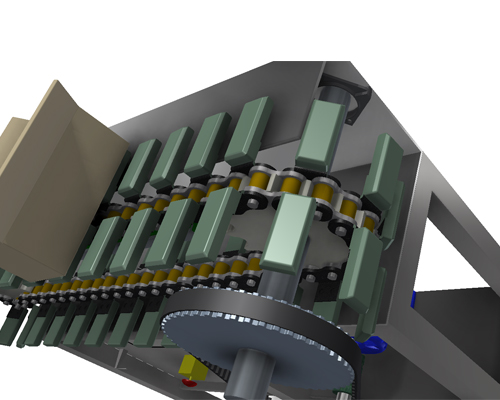

Roller chain system, elevator

Automated attached roller chain conveying system with PLC controller which can suit for a whole range of different requirements

- Heavy, wide, sensitive, bulk or liquid product can be carried through attachments

- Economic solution

- Up to 8m/s velocity

- Chain product range: standard (DIN8187, DIN8188), conveyor chains (M, FV series), extended pin chains, hollow pin chains, stainless steel chains

- Attachement type: A-1, K-1, M-1 etc., according to the drawing

- Can be expanded by internal manipulators and surveillance systems

Rollerchains are usually used to transfer high torque between two shafts.

The distance between two shafts can be more than 10 meters long but with accurate tensioner and guide the roller chain system can handle this sutiation easily and economically.

The standard chains has a wide range of sizes. The chain pitch can be between 3mm (small mechanic system) and 76,2mm (heavy industry). One of the standard tpye ultimate tensile strength can reach the 1720 KN! (48B-3).

The other hand the roller chain system has another very important advantage. Its the conveying ability. According to the custom made attachment every kind of material can be fixed to the attachment and can be transported safetily.

Under the roller chain category there is a special branch called elevators. This type of chain called Rédler which usually elevates forage to the silos. This type of system made of forged steel so it is capable to elevare tough elements like grinded stone.

Our system is capable to sense if the goods are filled in the cone and starts to elevate immediately thanks to the PLC controller system. So the elevator can be fed from hundreds of meter away (using another conveying element such as chain or belt).